Systems manufactured prior to 1972 used a single pneumatic lock pin with clevis on front of Set cylinder that secured the trust column by locking the sled to front of cylinder.

Systems manufactured prior to 1972 used a single pneumatic lock pin with clevis on front of Set cylinder that secured the trust column by locking the sled to front of cylinder.

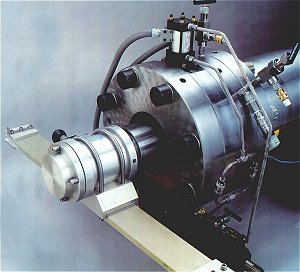

To convert the lock-pin configuration to the newer lock-yoke design. The existing front cover and lock bars are replaced with a new cover with two integral sliding locks which are pneumatically moved into position to secure the thrust column. A safety switch is located on the rails to assure the locks close only when the thrust is in the fully retracted position. In addition, the locks will only open if the carriage is in position.

This feature may be incorporated into either manual or automated control systems.

The Lock Yoke replaced the single lock pin to enhance safety, operation and convenience.

- Two smaller pneumatic cylinders mounted top and bottom

- Thrust column remains secure even if operation air is lost

- Sled can be moved to and from firing position without releasing the thrust column securing.

- Sensors on pneumatic cylinders to give positive feed back of status

- Reduces alignment problems sled to thrust column and sled to lock pin

- Bearing arrangement on front cover reduces fluid leakage from front of thrust column

- Interlock to issuer thrust column is in retracted position before engaging

- Lock yokes will only open when sled is in position to fire

- Reduces the weight of cylinder front end components – making maintenance easier

- Locking ring on front of sled is no longer needed reducing sled weight and increasing payload capacity

- No longer requires pit at front of rail system, reducing safety trip/ fall hazard