CLICK HERE FOR PRINCIPLE OF OPERATION

CLICK HERE FOR PRINCIPLE OF OPERATION

The 6-Inch Horizontal HYGETM system is designed to simulate the effects of a collision in an acceleration rather than deceleration mode. The 6-Inch Horizontal HYGETM system consists of a thrust piston with an acceleration stroke of approximately 24” (0.61 m). The system is capable of producing a family of acceleration wave forms with a nominal 40 ms rise time, using a standard metering pin. It is capable of a variety of metering pins that can produce a range of acceleration wave forms. This system design provides extremely repeatable and reproducible acceleration pulses, enabling accurate simulation and modeling of crash conditions in non-destructive fashion. The system has proven its repeatability over time. HYGETM systems over 40 years old routinely demonstrate repeatability of better than +/- 2%.

The test specimen is mounted to a carriage that is approximately 30 inches (0.76 m) wide by 24 inches (0.6 m) long and weighs approximately 165 lb (75 kg). This is attached to a rail system ~40 feet (12 m) long that has a spacing of 24 inches (0.6 m). Pneumatic brakes are mounted on the carriage. The maximum test specimen weight is 1,000 lb (455 kg). Additional rail sections and different carriage sizes are available.

The HYGETM system offers precise control of pulse shape, excellent test repeatability and universal acceptance within the automobile manufacturing community.

6-Inch Horizontal Applications

Systems are in use worldwide for a variety of automotive and aircraft safety testing applications. Some typical applications include the testing of components such as seats, seat belts, door lathes, windshields, transmission, engine, fuel tank mounts, body parts, etc.

Features & Benefits

- Proven Accuracy capable of simulating actual crash pulses to within +/-2%.

- Reproducibility pulses can be accurately reproduced.

- Versatility– Can perform a variety of velocity and acceleration tests.

- Mechanically Simple only 2 moving parts

Standard System Configuration

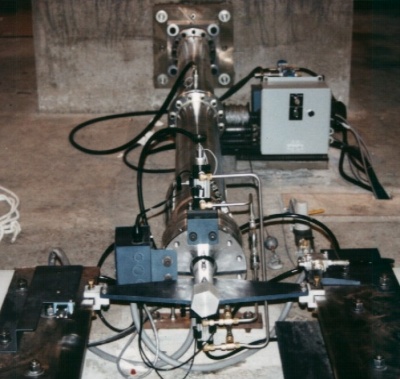

The 6-Inch Horizontal HYGETM system consists of four major components:

- The Actuator, including Load and Set Cylinders and the Thrust Column.

- The Rail System and Carriage.

- The Pneumatic System, which provides pressurized gas for firing the piston

- The Control Center containing hardware to pressurize and fire the system.

By changing to a different metering pin design, various pulse shapes can be produced. Low speeds and accelerations can be achieved without chatter.

Actuator

The actuator consists of two stainless steel cylinders each with a 6-inch bore. This is mounted to the face of a reinforced concrete foundation block. Adding or removing adjusts the volume of the Set Cylinder. The pulse control is done with a metering pin; the purpose of the metering pin is to throttle the amount of energy transferred to the carriage at any given time during firing, thereby determining the shape of the acceleration pulse. A particular component, in a particular crash situation, will have a waveform determined by modeling or by actual crash tests. Each metering pin is machined to produce the desired pulse shape for a given specimen and set of crash conditions. In addition, aspects of the waveform can be varied through changes in the Set cylinder volume and the gas pressures in each cylinder prior to firing. A metering pin, with the capability of producing a nominal 40 ms half-sine pulse, is provided as standard.

HYGETM offers a metering pin design program, which enables the engineer to enter the characteristics of the desired waveform and automatically generate the required metering pin profile.

Rail System and Carriage

The rail sections are precision ground on the top, bottom and inside edge to provide guidance for the specimen carriage. Each rail section includes the necessary anchor bolts, bolt positioning template for locating the bolts in the concrete foundation, the necessary nuts and washers.

A sturdy specimen carriage has a flat top with tapped mounting holes and the sides for equipment/specimen mounting. The carriage has pneumatic brakes on board which operate on the rail to stop the sled.

Pneumatic System

The primary energy source is an air cooled compressor, this is connected to a 10 gallon (38 L) accumulator tank.

Control System

The control system allows the operator to input the following parameters:

- Set Pressure

- Load Pressure

- Trigger Pressure

- Brake Pressure

The operator is led through the process in the proper sequence and prevents loading of incorrect, unsafe, or out of sequence parameters. Interlocks are hard wired to minimize errors.

The actual firing control can be performed manually from the panel. The operator loads the trigger pressure, disengages the lock yokes and begins the countdown sequencing to firing.

System Performance

The 6-Inch HYGETM is capable of producing a wide variety of shock pulses. A standard half sine wave metering pin is supplied with the system. The pulse may be modified by adjusting the HYGETM systems firing parameters. For example, lower pressures will have a direct bearing on the velocity at the end of the stroke.