Each of the systems in the HYGETM line of automotive safety test equipment includes a HYGETM actuator. The HYGETM unit develops its powerful, repeatable thrust through differential gas pressure acting on the two faces of a thrust piston in a closed cylinder.

Each of the systems in the HYGETM line of automotive safety test equipment includes a HYGETM actuator. The HYGETM unit develops its powerful, repeatable thrust through differential gas pressure acting on the two faces of a thrust piston in a closed cylinder.

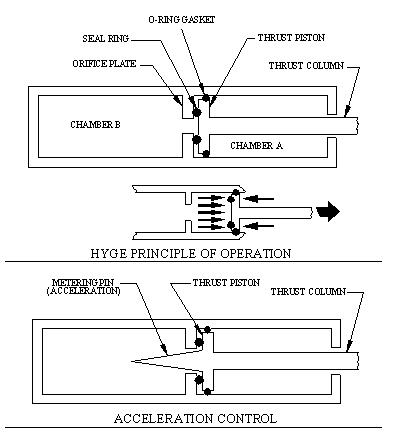

The cylinder is separated into two chambers by an orifice plate. The area of one entire piston face is exposed to the gas pressure in chamber A. On the other side of the piston, only the smaller area within the seal is exposed through the orifice opening to the gas pressure in chamber B.

In preparation for firing, compressed gas is introduced into chamber B until the forces on the thrust piston are equalized. Any further increase in the pressure in chamber B upsets this equilibrium, opens the seal at the orifice, moves the piston away from the orifice plate, and instantly exposes the entire piston area to the gas pressure in chamber B. A controlled thrust on the piston results. Transmitted by a thrust column, this limited-duration thrust acts upon a test specimen to produce an accurately predictable acceleration or velocity.

The thrust and the mass of the specimen govern acceleration of the specimen. To produce a given acceleration waveform, a specific metering pin is attached to the thrust piston and projects through the orifice into chamber B. The contour of the pin meters the flow of gas through the orifice, regulating the acceleration and making the utilized thrust precisely repeatable.

When the unit is used as a velocity generator, the necessary control is obtained by changing the pressure magnitudes.

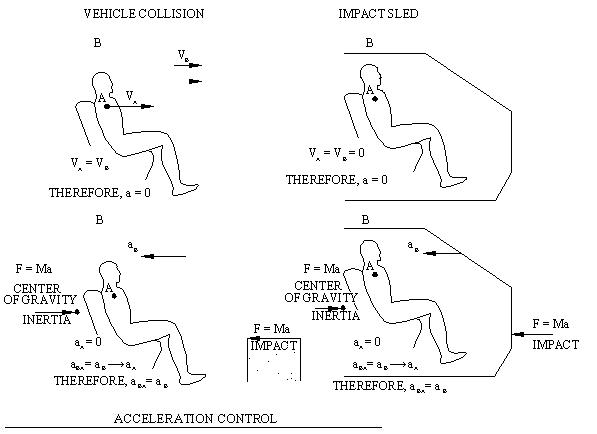

The HYGETM principle, as applied to safety testing, simulates the longitudinal deceleration conditions of an actual impact, but in reverse. Prior to an actual crash, the test vehicle and manikin each move at constant velocity. At impact they are stopped very rapidly.

The HYGETM principle, as applied to safety testing, simulates the longitudinal deceleration conditions of an actual impact, but in reverse. Prior to an actual crash, the test vehicle and manikin each move at constant velocity. At impact they are stopped very rapidly.

With the HYGETM system, the test vehicle assembly and the manikin are initially at zero velocity. This situation simulates the constant velocity conditions prior to an actual crash.

The programmed rapid acceleration of the HYGETM sled drives the automobile assembly out from under the manikin and produces a response similar to that caused by the rapid deceleration of a moving vehicle. The acceleration and deceleration effects are interchangeable because the acceleration-time relationships are essentially the same in both cases.

The acceleration control illustrations show the velocity and acceleration relationships between an actual crash impact and a HYGETM simulation.

Some significant advantages of the application of the HYGETM principle to crash simulation testing are:

- The manikin can be accurately positioned prior to the test and the position will remain unchanged until the instant of impact.

- Prior to impact, the manikin and the seat assembly are not subjected to forces caused by compressed seat springs or energy stored in the manekin.

- The zero acceleration level of the manikin prior to impact closely simulates real constant velocity conditions.