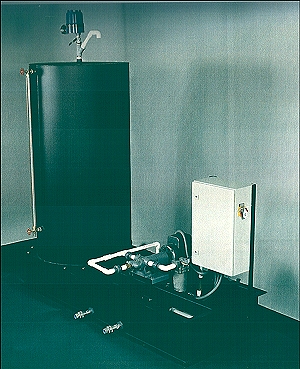

Automated Hydraulic System The Hydraulic Reservoir and Transfer System provides the means of varying the volume of the cylinders prior to firing. Control is from the Automated Control System upgrade which must be installed.

System Features:

Reservoir (tank) is of adequate size to store all of the hydraulic fluid even if both cylinders are emptied for maintenance. A fluid level sensor is used to measure the height of fluid in the tank. This is used by the computer program to determine the set and load lengths (volumes) of the cylinders.

Reservoir (tank) is of adequate size to store all of the hydraulic fluid even if both cylinders are emptied for maintenance. A fluid level sensor is used to measure the height of fluid in the tank. This is used by the computer program to determine the set and load lengths (volumes) of the cylinders.

Pump to transfer of the fluid to cylinders routing of the fluid is done by valves controlled by PC of the automated control system.

Tank, pump, valves and associated piping are mounted on a steel frame for ease of installation.

Propylene glycol (which is environmentally benign) is standard, but other fluids can be provided, if desired.

Manually activated safety valves for the Actuator fluid inlets. These valves are fitted with sensors to provide positive feed back of valves position to the interlock system to insure they have been closed prior to system charging

Hydraulic hoses to connect the Transfer and Reservoir System to the Actuator.

Note that fluid flow out of the cylinders is accomplished by applying low gas pressure to the cylinders and controlling valve actuation via Automated Control program to control fluid flow.