Emergency Brake

Earlier HYGETM carriages did not include an emergency brake system to prevent over travel as is standard today.

Earlier HYGETM carriages did not include an emergency brake system to prevent over travel as is standard today.

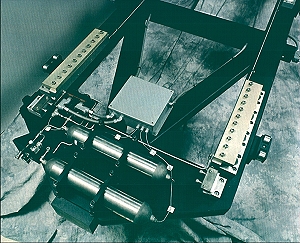

HYGETM can provide parts, instructions and install emergency braking on these existing sleds. The hardware consists of an on-board tank, valve, transducer and switch.

Emergency brake system consisting of an on-board storage tank, valve, pressure transducer and actuating switch. A ramp (cam) is positioned along the track with magnets or mounting brackets, should the carriage proceed too far down the track, the ramp trips switch to open the tank valve and 500 psi is dumped to the brakes to quickly stop the carriage. Since the switch is a normally closed type and the valve is a normally open, any interruption of power, such as a damaged umbilical cable, will act as a fail-safe.

Delayed Brake (whip lash)

This option allows the operator to apply a braking force to the carriage at some point after the initial firing for:

- Whip-lash component test

- Operation in conjunction with the standard brakes

- System may be fired with out initial brake pressure to increase velocity and/or payload .

The delayed brake system operates independent of the emergency brake system. The hardware consists of an on-board tank, valve, transducer and switch.

The operator can fill the tank at any pressure up to 500 psi.

The brake timing can be accomplished by two different methods:

- Ramp (cam) located at the desired position on the rail trips system

- May also be activated by PLC time, using trigger valve actuation as To . Note that the time increment is in 10 ms intervals.