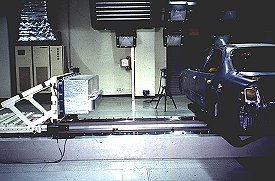

The Side Dynamic Emulation Procedure ( SIDE) is a developed and proven system supplied by HYGETM. This is accomplished by two sleds the vehicle sled (Black) and the impact sled (White). The vehicle sled is positioned at a determined location and the impact sled with a deformable element attached is accelerated by the HYGETM. It strikes the vehicle on the second sled.

The Side Dynamic Emulation Procedure ( SIDE) is a developed and proven system supplied by HYGETM. This is accomplished by two sleds the vehicle sled (Black) and the impact sled (White). The vehicle sled is positioned at a determined location and the impact sled with a deformable element attached is accelerated by the HYGETM. It strikes the vehicle on the second sled.

Units are operated internationally.

Function

- Emulates full-scale crash to Federal and European regulations.

- Utilizes the HYGETM reverse acceleration system

- Allows side impact development to be performed using body shell, stick side trim and restraint system components.

- Cost effective tool for the development and investigation of vehicle body shell construction.

Components

- Two braked sleds with ballast weights and control console

- Both sleds operate on standard HYGETM standard rail system

- The struck sled carries the vehicle body shell and is ballasted to correct vehicle weight.

- The vehicle sled brake can be adjusted to simulate the restraining forces between tire and road.

- The striking sled is equivalent to the full scale barrier and maybe configured to Federal or European standards.

- The striking sled carrier has the specified deformable barrier element.

- The ballast allows the weight of both the struck and striking sled to be set to applicable test requirements.

- The control console is used for setting the various brake pressures and integrating system into existing interlock system.

Operation

Operation

- The struck sled is positioned at prescribed location on rails in front of the deformable barrier element of the striking sled.

- The striking sled is positioned against HYGETM piston

- The HYGETM is used to accelerate the striking sled to required velocity.

After the test the sleds are both stopped using onboard braking systems.

Benefits

- Provides cost effective alternative to full scale side crash testing by using HYGE test facility and eliminating the need for fully-built test vehicles.

- Provides repeatable test conditions.

- Correlation with the crash test

Training and Commissioning

Training, installation and commissioning of the equipment are available.